Nano-CT

Research area nanoCT systems

The section for Nano CT Systems has the task of researching and further developing new techniques of the highest resolution computed tomography on the laboratory scale. Three unique research machines with the most modern methods are used to pursue different approaches in order to enable three-dimensional investigations on the nanometer scale, far beyond the resolution of conventional optical microscopy. As a simplification it can therefore also be called 3D microscopy with X-rays.

Nano tomography is thus a non-destructive and volume-imaging method and is therefore differentiated from established surface investigation methods such as SEM or destructive methods such as FIB tomography, which are otherwise used for sub micrometer studies.

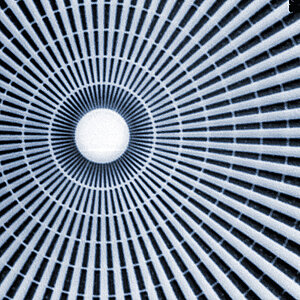

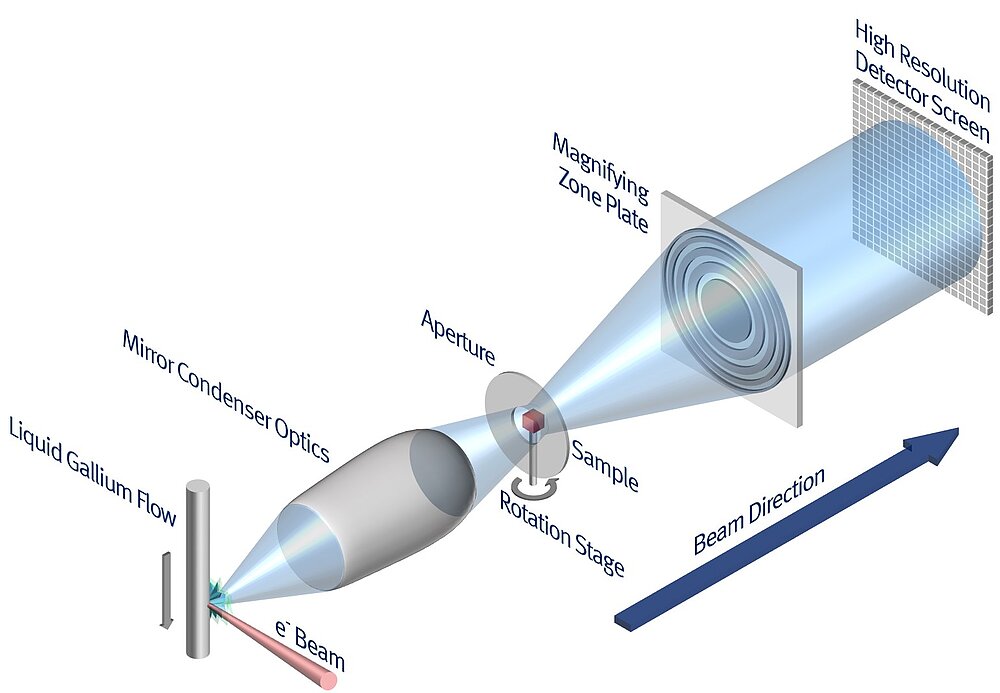

The TXM is a research setup with the aim to achieve the highest resolution on the laboratory scale due to the application and evaluation of state-of-the-art X-ray optics. These optics are a relatively new field of research, since X-ray radiation intuitively cannot be manipulated by classical lenses. In a spacious radiation protection hutch with numerous remotely controllable nano positioning systems, the TXM offers a great deal of freedom for the realization of new experimental set-ups. Most people are familiar with the principle of a simple tabletop microscope. The light from a lamp is bundled by a lens and passes a specimen, while a second optical system projects the image highly magnified into the observer's eye. The TXM uses state-of-the-art X-ray optics to replicate this beam path in order to exploit the advantages of X-rays such as the penetration of matter and short wavelengths. Various capillary and mirror optics are used as condensors, as well as diffractive zone plates (Fresnel lenses) and refractive lenses as imaging systems.

A high-performance microfocus tube is used as X-ray source. The special feature is the liquid metal jet system serving as an anode. A liquid gallium alloy is injected at high pressure into the vacuum chamber and is used as a constantly renewing target for the electron beam. The jet system offers a much better heat dissipation than conventional anodes and therefore allows a much higher power to be deposited on a small focal spot.

Schematic structure of the optics-based X-ray microscope setup with designation of the essential components in the beam path. Easy to recognize the parallels to the corresponding components in a classical full-field microscope.

Various X-ray optical components in the beam path of the system arranged for an experiment. For multi-axis remote alignment in the beam path, all components are mounted on more than 30 nanopositioners.

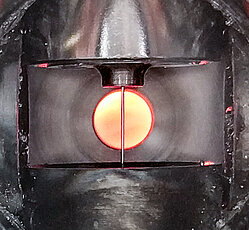

View into the vacuum chamber of the X-ray tube. From above, a liquid gallium alloy at 200 bar pressure is injected through a sapphire nozzle into the vacuum chamber in order to serve as a constantly renewing X-ray target. In the background, you can see the glow of a heated graphite foil to protect the beryllium window behind it against impurities.

In a close cooperation between the chair and researchers of the Fraunhofer Group Nano CT Systems it was possible to successfully develop a compact nano CT system with outstanding performance compared to commercial systems available on the market so far. The ntCT is based on state-of-the-art technologies in the field of X-ray tubes and detectors and allows the three-dimensional examination of objects with a resolution down to 150 nm. Due to its fully integrated system design and intuitive user interface, the ntCT is a close-to-market system and therefore also a showcase for the instrument development capabilities

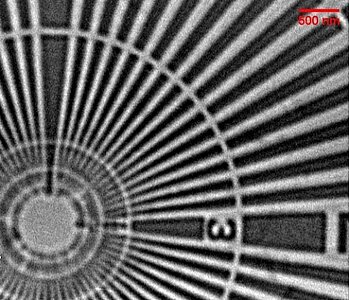

The magnification of the sample is based on geometric magnification, well known from the intersept theorem. For this purpose, the sample must be prepared as small as possible and positioned as close as a few hundred micrometers to the exit window of the X-ray source. A multi-axis sample manipulator with nanometer accuracy is available for this purpose. The X-ray source generates a source spot of only 300 nm on a tungsten transmission target. The radiation image is taken by a direct photon counting X-ray detector with 75 µm pixels. The ntCT is available to the chair for the investigation of various samples from the fields of materials science, microelectronics and biology.

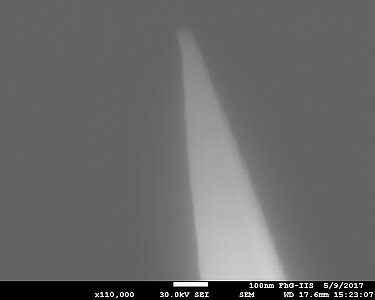

The XRM-II nanoCT is a CT system which is integrated into a scanning electron microscope (SEM). Like the ntCT, it is based on the principle of geometric magnification, so that a smallest possible focal spot is required. This is ensured by the focusing electron optics of the SEM and the specially manufactured tungsten/molybdenum reflection targets. The targets are shaped like a needle with a tip diameter of less than 100nm. With this system, resolutions below 100 nm in 2D and 130 nm in 3D can be achieved.

The XRM-II nanoCT is designed to still provide the full functionality of an electron microscope despite the CT addition. This has the advantage that samples can be examined not only with X-rays but also with electrons.

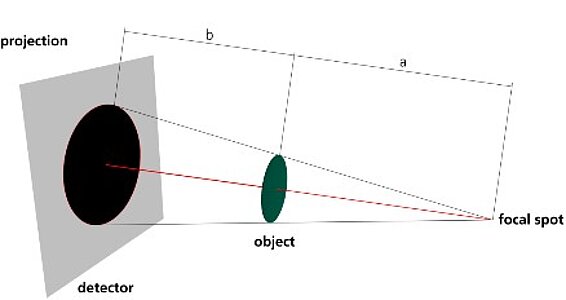

Principle of geometric magnification:

the magnification is given by the ratio of the distances between source detector (a+b) and source object (a).

The special and specific requirements of X-ray systems require the use of tailor-made detector systems. Therefore, it is also part of the department's work to develop novel X-ray scintillation detectors in hardware and software. An important component for the optimization of detector efficiency is the understanding of the underlying mechanisms and the development of theory.

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/5/0/csm_Startseite_SAXSAnlage_V2_Fuchs_e4c1b4e130.jpg)