X-Ray Scattering

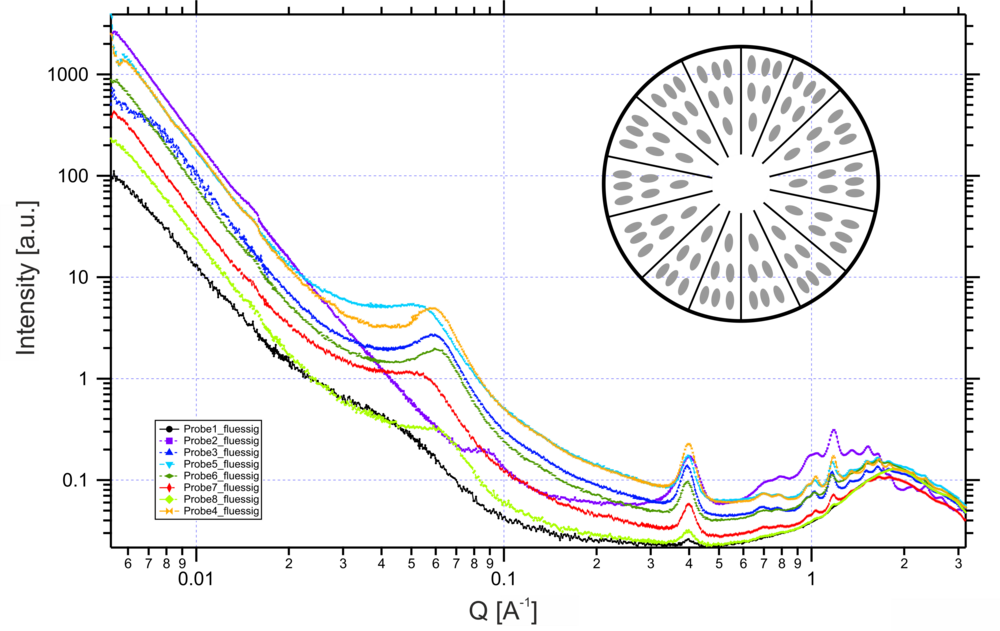

Small-angle-X-ray-scattering, SAXS is a common method of material characterization. Possible samples can be examined in a solid state (e.g. powders, alloys, aerogels, woods, collagen) or as a solution (e.g. colloid solutions, polymer-solutions, stabilized nanoparticle solutions, active ingredient formulations) (see ill. 4 and ill. 5). Basically, the following information can be obtained using the SAXS

- Size and shape of the components of the sample

- Structure of the sample

- Particle orientation

Unlike electron microscopy results, the results from the SAXS are not just valid for a small random sample. Using the information about a large number of particles in the sample, we can draw statistically robust conclusions, e.g. information regarding the size distribution.

In addition to this, the intensity measured can be calibrated so that it corresponds to the differential cross-section of the scattering process used. This is described as absolute calibration. The calibration standard used at the LRM is a Glassy Carbon Reference (https://usaxs.xray.aps.anl.gov/documentation/glassy-carbon-standard) measured at the Advanced Photon Source (APS, Argonne National Laboratory). By using this type of calibration, more complex properties can be determined, such as the electron density distribution in the sample or the hydration level of colloids in a solution.

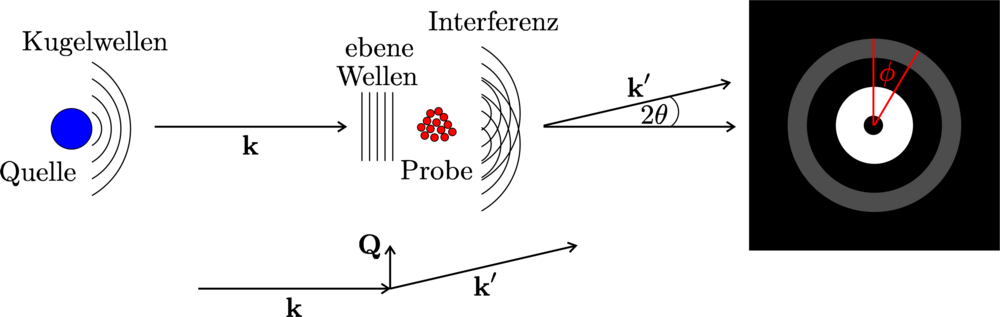

The source generates x-ray radiation, which is seen as a plane wave front (k) at a sufficiently large distance. The interference of the resulting spherical wave (k) caused by the interaction with the sample, is visualized on the detector. For the analysis and theoretical modelling, the 2D-detector image is reduced by azimuthal integration to a 1D-scatter profile (as a function of the momentum transfer Q).

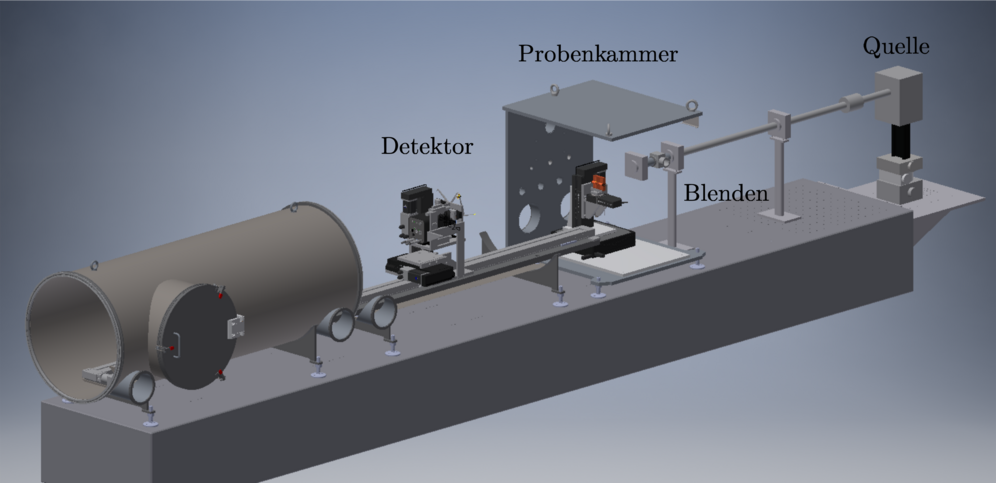

With the present SAXS-setup at the LRM, the distance between sample and detector can be adjusted continuously between 6 cm and 3.5 m. Thus, a combination of small- and wide-angle measurements are possible without changing the sample and/or modifiying the setup. The effective obtainable specifications of the plant are:

- Angle range: 60° up to a few degree-minutes

- Wavelength used: 1.5 Å (Cu-Kα1:Cu-K α2=2:1)

- effective Q-range: 0.005 – 5 Å-1

- corresponding sizes in real space which can be examined: 5 Å – 150 nm

With suitable samples, the resulting reduced scattering profiles can deliver five full sizes of scattering intensity over three full sizes of momentum transfer Q (see ill. 3). This is comparable to the results obtained using synchrotron radiation!

A range of different sample environments is available for testing. If necessary, samples in a liquid state can be kept at a temperature of between -5 – 80 °C during testing.

These images were recorded using various sample-detector-distances d: a) d=6 cm, b) d=60 cm. The exposure time for each was two minutes. Silver behenate is a crystalline power with a very large lattice spacing of 5.84 nm. For this reason, it is used as a standard for the spacing calibration for SAXS. The bar in the middle of the image is necessary for the read-out-electronics of the detector.

Scattering signal for a 30 weight percent (wtp) aqueous Pluronic-P123-solution without (a) and with (b) stabilized cadmium sulphide-nanoparticles at a temperature of 30°C (Exposure times: two hours each). In a) the liquid-crystalline phase of the resulting micelles of the aqueous P123-solution can be observed based on the occurring Bragg reflexes. Due to the stabilization of the cadmium sulphide nanoparticles in b) the detector image changes drastically. The regular occurrence of reflexes in almost perfect rings shows the high intermittency in the arrangement of the polymer-nanoparticle-aggregates. The bar in the middle of the image is necessary for the read-out-electronics of the detector.

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/5/0/csm_Startseite_SAXSAnlage_V2_Fuchs_e4c1b4e130.jpg)